|

| May 14, 2019 | Volume 15 Issue 18 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

How pressure-sensitive paint helps improve hypersonic flight predictions

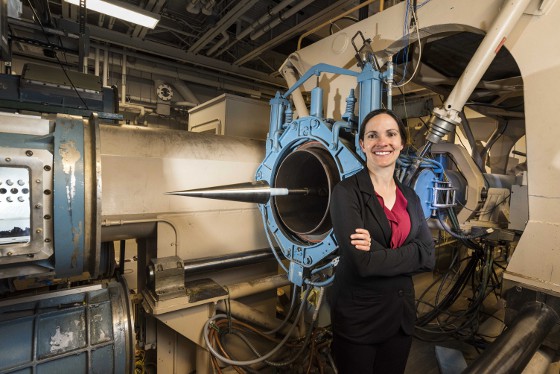

Aerospace engineer Katya Casper has become known for her innovative techniques measuring the effects of pressure on hypersonic vehicles at Sandia National Laboratories' wind tunnels. [Photo by Randy Montoya]

When traveling at five times the speed of sound or faster, the tiniest bit of turbulence is more than a bump in the road, said the Sandia National Laboratories aerospace engineer who, for the first time, characterized the vibrational effect of the pressure field beneath one of these tiny hypersonic turbulent spots.

"The problem is that these patches of turbulence are really fast and really small," said researcher Katya Casper. "There are thousands of turbulent spots every second in hypersonic flow, and we need really fast techniques to study their behavior."

The pressure field is key to understanding how intermittent turbulent spots shake an aircraft flying at Mach 5 or greater, Casper said. Hypersonic vehicles are subjected to high levels of fluctuating pressures and must be engineered to withstand the resulting vibrations.

Simply put, being able to characterize and predict these pressure spots leads to better vehicle design.

"The understanding of unsteady pressure fields is extremely important for modeling of hypersonic flight vehicle applications for a variety of national security programs," said Basil Hassan, senior manager in Sandia's Advanced Science and Technology Program office.

"This advanced diagnostic development work forms unique datasets for fundamental discovery and model validation at Sandia and has been used to improve flight predictions for several national hypersonic flight programs," Hassan said.

Over the past several years, Casper's experiments have progressed from the use of miniature electronic sensors to advanced imaging techniques with pressure-sensitive paint, which is applied to a model tested in a wind tunnel and viewed by specialized cameras to measure the pressure fluctuations optically.

The American Institute of Aeronautics and Astronautics cited Casper's breakthrough in characterizing hypersonic turbulent spots and her work with novel fluctuating pressure instrumentation when announcing earlier this year she had won the organization's Lawrence Sperry Award, given for notable contributions in the field by a person age 35 or younger.

How turbulent spots vibrate hypersonic vehicles

Casper's experiments characterizing hypersonic turbulent spots used innovative diagnostic techniques to provide insight into the interaction between pressure fluctuations and vehicle structural response.

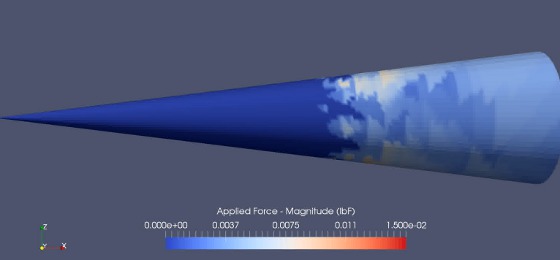

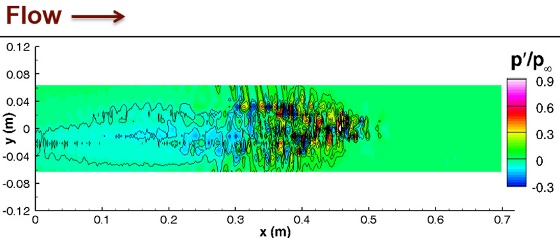

With advanced imaging techniques and high-speed sensors, the work showed that transitional pressure fluctuations are generated by intermittent turbulent spots that pass by in a millisecond. As the spots grow, they merge into a fully turbulent layer. The data Casper captured was instrumental in improving predictive computer simulations developed by her colleagues at Sandia.

The pressure footprint of one hypersonic turbulent spot at Mach 6. As turbulent air flows over an object, thousands of such spots occur every second causing severe vibration. [Graphic by Katya Casper]

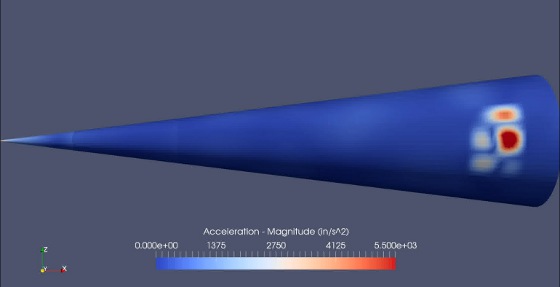

Using a cone-shaped model with an integrated thin panel embedded with pressure sensors and accelerometers at Sandia's hypersonic wind tunnel, Casper studied the response, or vibration, to turbulent spots.

When the frequency of the passing turbulent spots matched the natural structural frequency of the panel, strong resonance was generated with vibration levels more than 200 times larger than when the spots were mismatched to the panel, she said. "This would be a worst-case scenario for the flight." Now engineers have an improved means of predicting such a scenario and adapting to it.

Blasting paint to measure pressure

A lot of Casper's work occurs at Sandia's wind tunnels, but it doesn't stop there. Last year, Casper migrated similar pressure diagnostics to Sandia's blast tube to demonstrate in larger field tests the pressure-sensitive paint technique first used in the wind tunnels. She combined intricate lighting, high-speed cameras, and the carefully formulated chemistry of pressure-sensitive paint to capture the effect of a shock wave rolling across a vehicle.

Like the turbulent spots in the wind tunnel, the shock wave creates unsteady pressure loading that can vibrate a flight vehicle.

With an explosive charge detonated at one end of the 6-ft-diameter blast tube, a shock wave travels through the tube before hitting a model at the other end. Traditionally, hundreds of small pressure sensors would be placed on the model to measure the force. Instead, Casper proposed using pressure-sensitive paint.

"With sensors, you can only get pressure readings at the discrete locations of where they're placed," Casper said. "With the paint, you can get data everywhere."

In August, the paint (which is mixed at Sandia and based on this formulation) was airbrushed on a model nose cone. Four high-powered, water-cooled ultraviolet lights were shone on the pressure-sensitive paint, causing it to fluoresce. The more oxygen the paint is exposed to, the less it fluoresces. The greater the pressure, the greater the oxygen. So as the shock wave from the blast passed over the model, increasing pressure on its surface, the intensity of the paint's glow decreased.

Click the image to see the structural response on the panel embedded with sensors. [Videos by Brian Robbins]

Caught on a high-speed camera shooting at 25 kHz (or 25,000 cycles per second) with a filter used to block the ultraviolet lighting, the result is a dark shadow growing over the model from the tip to the base; and then as a reflected shock passes by, the shadow encroaches from base to tip.

The change in the paint's florescence can be calibrated to the amount of pressure exerted on the model.

Casper and team conducted eight blast tube runs over two days and learned a few valuable lessons from the first-of-their kind tests. For example, the tests collect better data when it's dark, or at least cloudy, as sunlight interferes with the paint's florescence.

"It's a new approach for measuring pressure taken to the blast tube," she said. "Overall, the tests were successful, and with a few adjustments should ultimately be useful in determining how to protect objects from shock waves."

Sandia National Laboratories is a multimission laboratory operated by National Technology and Engineering Solutions of Sandia LLC, a wholly owned subsidiary of Honeywell International Inc., for the U.S. Department of Energy's National Nuclear Security Administration.

Source: Sandia

Published May 2019

Rate this article

View our terms of use and privacy policy